- Share

FAQ

We can assist with distributors’ training, pre-sale & after service support, product technical specification & drawing, and many others. Reach out and let us know how we can tailor our products and services to better serve you.

Disinfection

The most common form of algae in swimming pools is “green” algae. It can cling to the wall or float in the water. Do pool water pH analyze to ensure the pH is at the proper level. Balance the water chemistry if needed. Install salt chlorinator is the best disinfection system to kill algae to kill water crystal without green algae. The alternative is to use UV-C lamp.

Even the chlorinator is design in auto cleaning function but there is calcium scale build-up on the cell. It is still need to clean it at least every 6 month for maintenance. Otherwise, the chlorinate generation will be decreased and pool water become green by algae. Also, it will shorten the lift time of the titanium cell.

Procedures

- Make a cleaning mixture of 1/10 parts Hydrochloric Acid to water (always add Hydrochloric acid to water).

- Turn the filtration system off.

- Remove Salt Cell from the housing.

- Add the Salt Cell to the cleaning mixture making sure there is little to no contact with the terminals.

- Wait five to ten minutes for the Salt Cell to be cleaned.

- If any parts of calcium are stuck or will not dissolve, carefully remove them with a smooth plastic instrument.

- Once the Salt Cell is clean, rinse with fresh water and place back in the housing and tighten the cell or collar.

- Turn system back to automatic setting or timer.

- Dispose of cleaning mixture.

If the Salt Cell has an increased amount of calcium and it has not been removed after the ten minutes in the cleaning solution it is advised to use a specialty product “Cell Cleaner” which is not as corrosive or damage the cell in any regard. The cell can be left in Salt Cell Cleaner for up to 1 hour and will completely remove calcium.

Filter

As a general rule of thumb, sand filters typically max flow rate is 36.6m³/h/m² (15 Max gpm / ft ² base on ANSI-15) of filtration area. Therefore, the below table can be applied for sand filter size determination.

Flow Rate (gpm) | Filter Area | ||

gpm | m³/h | ft ² | m² |

40 | 11.08 | 1.8 | 0.17 |

50 | 13.85 | 2.3 | 0.2139 |

60 | 16.62 | 3.1 | 0.2883 |

100 | 27.7 | 4.9 | 0.4557 |

(Filter media)

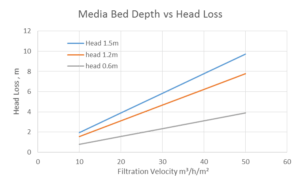

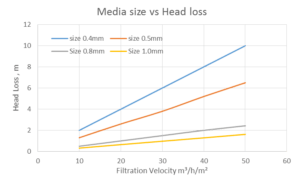

The fineness of sand media size , the higher head loss. It is truth for deeper bed depth with higher head loss. They are illustrate as figures.

|  |

Pump

It is likely that the bearing is worn. The pumps bearing allow the drive shaft to pass through the pump housing and attach to the impeller. A squeaking or clicking sound coming from the bearing is a warning sign that they are wearing and in danger of breaking. Worn or noisy bearing should be replaced immediately to prevent further damage to any related components. All bearings will wear over time with regular use and will require replacing eventually.

- Turn off power to the pool pump. Never, ever, service your pool equipment with the power on.

- Relieve built-up pressure (For cartridge & de filters only)

- Record the pressure on the filter pressure gauge, typically it will read between 15-20 psi (pounds per square inch). Relieve the pressure by turning the air relief valve on top of the filter counterclockwise. Water will spray out of the valve while the pressure gauge decreases to 0 psi.

- Remove the pump transparent lid by hand only.

- Mark the basket position and remove it from the strainer. Use a garden hose to rinse out the debris. Baskets will become brittle and can break easily over time. Inspect the basket for signs of damage. Reinstall the basket with marked position.

- It is necessary to check the O-ring for stretching, tears, cracks, or any other damage before install the Lid transparent Lid and nut. You can apply a thin coat of lubrication on the O-ring; this will help seat the gasket and prolong its life.

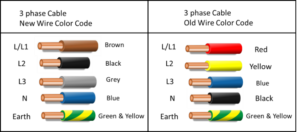

The latest cable color code is Brown for L1, Black for L2 , Grey for L3 , Blue for Neutral and Green & Yellow for Earth.

For old code it is Red for L1, Yellow for L2, Blue for L3 , Black for Neutral and Green & Yellow for Earth.

DOL starting is the simplest, cheapest and most common starting method. It actually gives the lowest temperature rise within the motor during startup of all the starting methods. But the drawback is starting current can be 3-8 time of full load current. Therefore, it is not recommend for pump power higher than 5.5KW in public low voltage mains 400V.

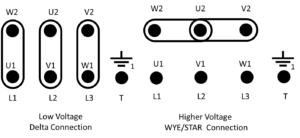

DOL Starter can be applied to motor connect in Delta or WYE/Star connection.

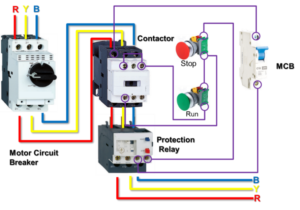

The typical common 3 phase pump Run / Stop starter is Direct-On-Lone Starter that include:

- Motor Circuit Breaker is a short circuit magnetic protection devices.

- Control unit for Run and Stop operation and status monitoring.

- Protection relay is an overload thermal protection device.

- Single phase MCB for secondary protection.

![]() It is a typical wiring diagram without ground wire for reference only. All electrical rating of individual device has to match with pump’s current rating specification.

It is a typical wiring diagram without ground wire for reference only. All electrical rating of individual device has to match with pump’s current rating specification.

Open the terminal box on the top of the motor, there are six terminals and Ground. It can be connected in Delta or WYE/STAR connection. 380VAC 50 Hz +10% and -6% electric power is three phase power source voltage range.

First of all, you need to know the pool volume and then apply minimum 6 hours filtration cycle. The longer water circulation turnover time is encouraged.

Most in the industry size for a single turnover in 8 hours – even though 12 hours (the ANSI-5 minimum) would be more efficient.

15,000gpm÷ 8hours ÷ 60 minutes = 31 gpm.

For a 15,000 gallon pool, common practice was to install at least a 1 h.p. pump and run it 8 hours.